|

Ergonomic and efficient formulation dispensing systems ...fully automatic, semi automatic... single level or through the floor design. For one-man operation with a throughput of 3000 kg / shift can be achieved.

|

|

|

|

Classical rapid-mixer fluidbed dryer systems... fluidbed granulators and coating systems... exact end point determination by means of a seamless integrated PAT NIR system available.

|

|

|

|

One pot highshearmixers - granulator ... vacuum dryers harnessed with microwave technology. Top driven - easy inspect able systems with centre discharge.... fully CIPable as option.

|

|

|

|

More than 50 % of the manufacturing cost in the pharmaceutical industry are due to In Process Controls and laboratory expenses, i.e. related capital cost of storage of product waiting for the next batch-production step. Continuous manufacturing, supported by PAT tools can minmize these cost. The EASY FLOW® wet granulation system minimizes quality expenses, allows variable production of a recipe and does not require any scaling-up. This can speed up to six months when launching a new product... which can save millions.

|

|

|

Dry continuous granulation is the prime manufacturing method for any new solid drug development. Our principal from Germany, founded in 1981, is an experienced leader in the manufacturing and worldwide supply of advanced Roller Compaction and Granulation Equipment for the Pharmaceutical, Food and Chemical Industries. They are renowned for the quality and durability of its equipment range. They own many patents for their innovative technology while constantly developing their product range to remain as the technology leader for dry compaction processing.

The output capacities ranges from only 20ml on a specially designed micro dosing unit to over 30Tons/hr. In today’s cost critical markets continuous or semi-batch orientated dry powder compaction offers very attractive process conditions. So let us be your global partner for Roller Compaction technology. The offered product portfolio covers bespoke process solutions from feasibility studies to full production scale systems under contained conditions.

|

|

|

Container (IBC) blenders and stationary powder homogenising systems with capacities up to 20 000 litres. Due to special blending support elements in the vessel efficient homogenising with filling levels as small as 20 % and up to 85% can be achieved.

|

|

|

|

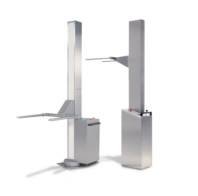

Bespoke IBC and drum handling systems, mobile and stationary... for loads up to 2000 kg and lifting heights reaching 12 meters !!!.

|

|

|

|

Vacuum conveyors and transfer systems for powder, dust, pigments, granulated material and tablets. Providing different modular families of vacuum conveyors for the chemical-, pharma- and food-industry allow customized design of all conveyors regardless of the individual application. Even critical materials can be conveyed safely. Tailored conveyors can be used for hazardous applications in explosion areas or with highly toxic materials. The modular design allows swift delivery time for the complete systems.

|

|

|

We have been innovator of the high speed rotary tablet presses to the Japanese pharmaceutical market since 1957 and offer lab scale / R&D and production tablet presses in conventional single layer, multi-layer, dry coater, WIP / containment, computer controlled/instrumented and exchangeable turret technologies. We provide also ancillary products and turn key engineering for upstream and downstream applications. With the subsidiary company in New Jersey USA and a global sales network we give high quality and responsible service to our customers. We strive to continue to setting the standards in mechanical design and tooling quality for the markets of Asia.

|

|

|

We provide Metal Detection Systems from a Market Leader that has been designing and manufacturing these devices for industrial applications for over 40 years. They feature extremely high detection sensitivity towards contaminating metals, whether ferrous, non-ferrous or stainless steel, even when these are present in tiny quantities.

Particular attention is being paid to the deflector opening/closing couple and to its geometric profile in order to prevent trapping the product during activation phases.The systems can be linked to local computer networks via a TCP/IP (Ethernet) interface or RS-485. Whether in stand-alone operation or centralised via a computer network, the Metal Detection Systems satisfy the standards of Security, Integrity and Traceability of production data as required by Part 11 of Title 21 CFR, Electronic Records and Electronic Signatures (ER/ES).

It goes without saying that we can integrate the Metal Detector also with a vertical Tablet Deduster ensuring Inline dedusting and deburring of any type of tablets.

|

|

|

Call it punch and die tooling, compression tools or tablet tooling, the final product is tooling that will produce a tablet that is incredibly important to your business. Our formula for success starts with the use of the highest quality tool steel, carbide and ceramic from the world's finest manufacturers. . . then incorporates skilled design engineering, the very latest in computerized machine tools, expert craftsmanship and a level of quality control that is unprecedented in the industry. Our coatings include: titanium aluminium nitride, Plasmachrome®, chromium nitride and diamond-like carbon.

Beside the cost-effective standard punches and dies we can provide unique pelleting tools for micro-tablets, multi-tip tools and perfect special shape tools... Whether it is a bear, gingko-leave or coffee-bean, almost any shape is possible.

|

|

|

Sugar coating pans and highly efficient perforated drum coaters, with double-helix technology to minimise coating time and reduce spray losses. Real CIP systems available... because of rack-mounted design installation and start-up possible within three weeks.

|

|

|

|

Secure protection of tablets without compromising easy dispensability is crucial, especially in tropical countries. Rapid and hassle-free filling of tablets into tubes is offered with a wide range of filling machines, from the smallest with a capacity of 35.000 tablets per hour to the most powerfull with a capacity of 160.000 tablets per hour, depending on the number of tablets per tube.

|

|

|

Economical Wash In Place (WIP) and fully automatic Clean In Place (CIP) plants, designed as standalone or Pharma production machine integrated systems. Built by the leading German manufacturer of hi-tech highly efficient washing and drying systems for recipients, drums, pallets, hoses and other accessories. Our main clients are the manufacturers of chemical and pharmaceutical products and its components. These systems have remarkable market share in the superior quality concerned markets. Worldwide references by major players are proof how their washing and cleaning can be improved.

|

|

|

|

The Japanese technology leader of high speed optical analysis of powder, granule or tablet images provides vision inspection systems to speedily remove out of specification items from the product flow in front of capsule filling, tablet pressing, blistering and packaging. Reliably ensuring the detection of diverse kinds of color contamination of powder, tablets, defective printing and the like using a own brand color line scanning camera. Processing capacity of up to 250,000 tablets per hour throughput can be achieved.

|

|

|

|

Disintegration testers for offline In Process Controls analyze tablets with new innovative concepts of data acquisition and data analysis. Each sampled data may be traced back to the batch, press, outlet, or even the container the sample had been taken from. Tabular and/or graphical reports may be printed for single tests, for the whole batch or any other level

|

|

|

Flexible and modular tablet testing systems for offline In Process Controls which automatically measure weight, thickness, diameter and hardness of tablets, dragees, oblong tablets, capsules and similar products. Our systems feature:

- solid, industrial design

- fully automatic operation

- reliable and quick measurement

- easy computer-assisted operation

- modular and expandable

- efficient tablet dedusting feature (option)

- very stable and highly precise weighing cell (option)

- innovative concept of tablet handling / orientation in the tester

|

|

|

Whispering vertical dedusters ensure dedusting and deburring of any type of tablets. The stepless vibration creates a vertical ascension of the products. For more than 35 years, the pharmaceutical industry has relied upon our principal to dedust, deburr and convey tablets with the highest efficiency. Over 5000 dedusters ensure a smooth operation daily at the sites of hundreds of pharmaceutical companies, ranging from multinationals to small local manufacturers of tablets and capsules.

Our customers appreciate the quality and reliability of our equipment. Our solutions offer superior performance and low costs over the whole product life-cycle. Our worldwide network allows us to maintain close ties with all users, resulting in optimum service and support.

|

|

|

70 % of all new drugs are high potent medicines such as immune suppressant or anticancer drugs. This pharmaceuticals require absolute protection of the operators from product - and product from the operators. We are prepared to offer the entire cleanroom technology spectrum to you. We focus on special design, including the complete project execution starting from the development phase through to qualification and maintenance. Thus, you can be certain that all project phases are executed and supervised by one single, competent partner. This helps you save valuable resources in terms of time, labour and money.

For small quantity manufacturing up to 40 kg we can provide barrier isolators (also called glove boxes), beyond that easy to clean and nano gramme performance double-split valves can be integrated with all Pharma-production equipment offered.

|

|

|